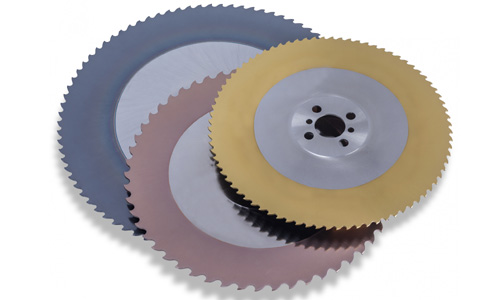

HSS Circular Saws

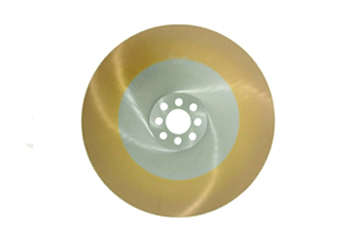

We are a Manufacturer and Exporter of HSS Circular Saws in India, the most demanded in the metal cutting industry. Our Circular Saws are made from the best quality metal DM05 for cutting various types of tubes, pipes, sections, and solid-based materials in ferrous and non-ferrous metals. These Circular Saws can be supply with all kinds of PVD Coatings.